MASTER, SPORT, FST.

The 1984 Model Range - Motivations

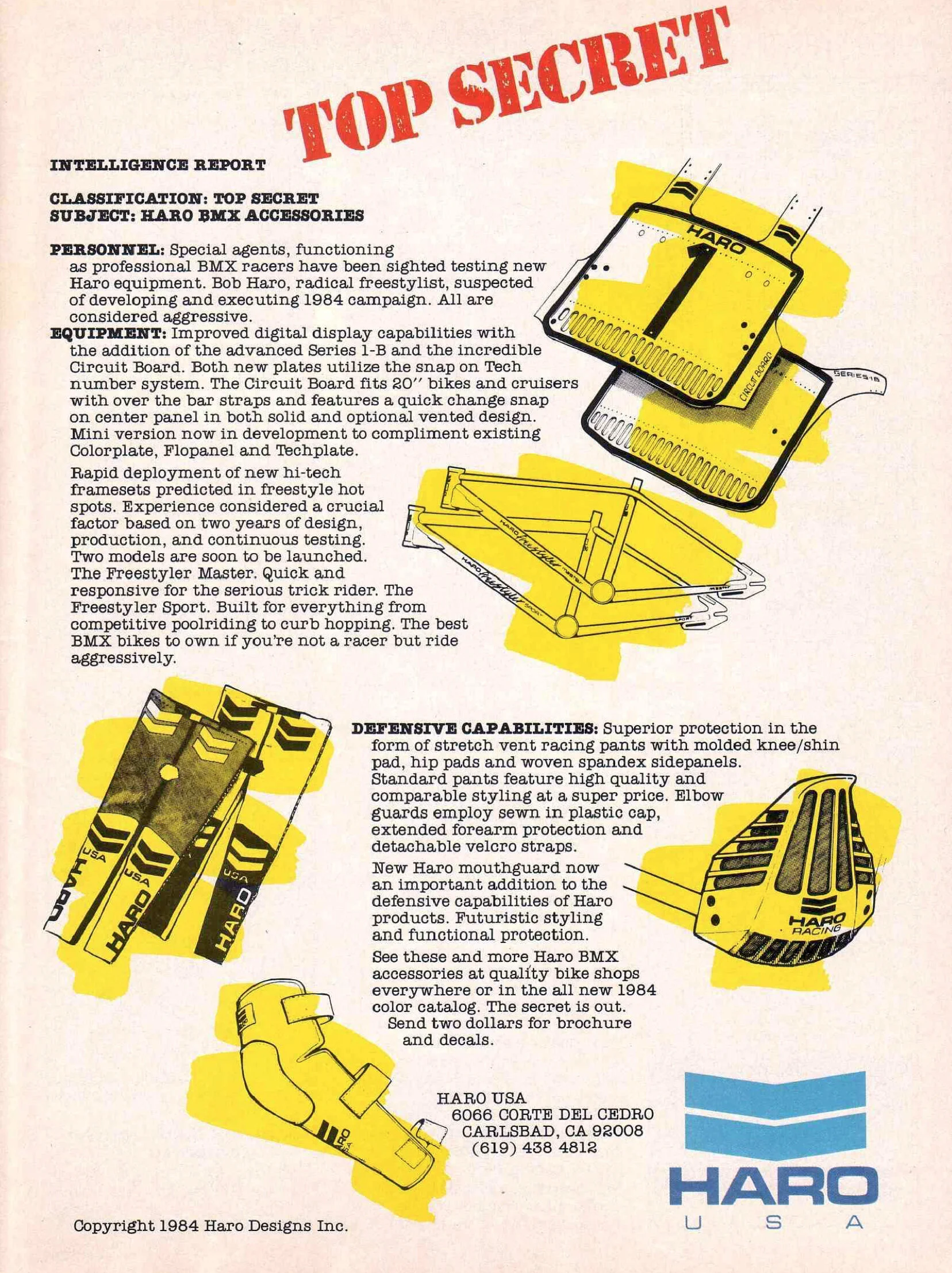

January 1984 – BMX Action Magazine: Haro’s “Top Secret” advert – “Rapid deployment of new hi-tech framesets predicted in freestyle hotspots. Experience considered a crucial factor based on two years of testing. Two models are soon to be launched. The Freestyler Master. Quick and responsive for the trick rider. The Freestyler Sport. Built for everything from competitive pool riding to curb hopping. The best BMX bikes to own if you’re not a racer but ride aggressively.”

Left: The original “Haro Freestyler Master” drawing- Winter 1983. Right: The “Top Secret advert. First published in January 1984.

Forensics

In the archives at Haro, exists a technical frame drawing, titled “Haro Freestyler Master.” Raised in the fall of 1983, the drawing reveals an unfamiliar looking frame with a series of design features that clearly differentiate it from the company’s flagship model; the Haro Freestyler. The frame features “swaged,” or “tapered” tubing in its rear triangle. The rear dropouts appear to be cut from flat Chromoly plate without the commonly seen holes - inserted for weight-saving purposes. The coaster brake anchor is integral to the design of the dropout and identical to the chrome single-top-tube Haro Sport prototype, briefly ridden by Rich Sigur in early 1984. Sigur recalls breaking the chrome frame at the chain stay - likely the outcome of riding with a coaster brake in skateparks. This two-dimensional frame drawing illustrates the start of the busiest twelve-month period of product development at Haro Designs during the 1980s.

The Haro Master vs. The Haro Freestyler.

The first generation Haro Master went into development in the fall of 1983, and its release the following summer set the standard for innovation. Where the Haro Freestyler beat a deliberate path away from BMX racing, it was the Master that legitimized freestyle and fueled an era of prolific growth at Haro Designs. The technical differences between the 1983 Haro Freestyler and the first generation Haro Master were negligible. A machined bottom bracket shell brought a marginal weight advantage to the Master, and a fully welded gusset at the head tube, and down tube junction, laid to rest any further issues with cracking at the front end. Aside from its new graphics, when compared side by side, the first generation Haro Master and the Haro Freestyler were hard to separate at first glance.

Evolution – The Second Generation Haro Master.

The second-generation USA Made Haro Master entered the market in July of 1984, and the frame was altogether more sophisticated than the model produced between March and June. This evolved version remained unchanged in its geometry but bore a much closer resemblance to the original 1983 drawing. The seat stays and chain stays were tapered and brought a sleeker aesthetic to the rear triangle. The coaster anchor, although strangely fragile looking and thin, was relocated to the top of the right chain stay, and swept into dropouts with flared undersides to increase rigidity. Paint and decals remained identical to the first generation Master. Both models were produced exclusively by Torker BMX in Fullerton, Orange County, California.

The complete 1984 Haro Master.

Prior to 1984, all Haro frame and fork models were produced in partnership with Torker – an established BMX race brand founded in Anaheim, California, in 1976 by an aircraft test pilot named John Johnson. The relationship between Haro and Torker was productive. Bob Haro was sponsored by the brand, and he rode their LPX twin-top-tube race frame in his early freestyle shows. Torker's unique, in-house manufacturing resources enabled Haro Designs to diversify from marketing number plates and apparel and take a step into the global bicycle industry.

But the price of success presented challenges to both Haro and Torker. Demand for the Freestyler escalated in 1983 putting pressure on Torker's Fullerton based workshop. Exploratory discussions with other local frame builders - rumors of sample frames produced by Voris Dixon at VDC, and an unknown machine shop in southern Los Angeles, remain just that – but the fact is that Haro and Ford were keen to find a back-up source to support the company's growth. Many indicate that Torker's failure to develop a freestyle bike in their own model line contributed to the difficulties they faced in the winter of 1984. What is certain is that Torker continued producing frame and fork sets for Haro right up until they finally closed the business in November of 1984.

The Torker relationship remained strong, although with the market potential becoming more obvious, Haro and Ford were keen to find a back-up source to support the company's growth. The decision to manufacture outside of the United States wasn't taken lightly. A period of due diligence led Jim Ford and Bob Haro to Taiwanese brothers; Sam and Alan Wong (pronounced Wang). TEEL Industries, a trading company in New Jersey owned by industry veteran Taka Nieda, that specialized in connecting US-based brands with Asian factories, made the introduction. The brothers owned and operated – Anlun Enterprises - specializing in the manufacturing of cast and machined components - and Anlen - a frame building and assembly factory. Both facilities were located in the Taichung district of Taiwan. The breakthrough happened in the summer of 1984. Haro delivered the Haro Master, Sport, and FST as complete bicycles built with a range of components supplied by several industry-leading, component companies. As well as being partially-assembled in the box, the frames were even more refined than those made at Torker - with stamped chevron logos on the head tube gusset and capped seat, and chain stays.

The Haro Sport

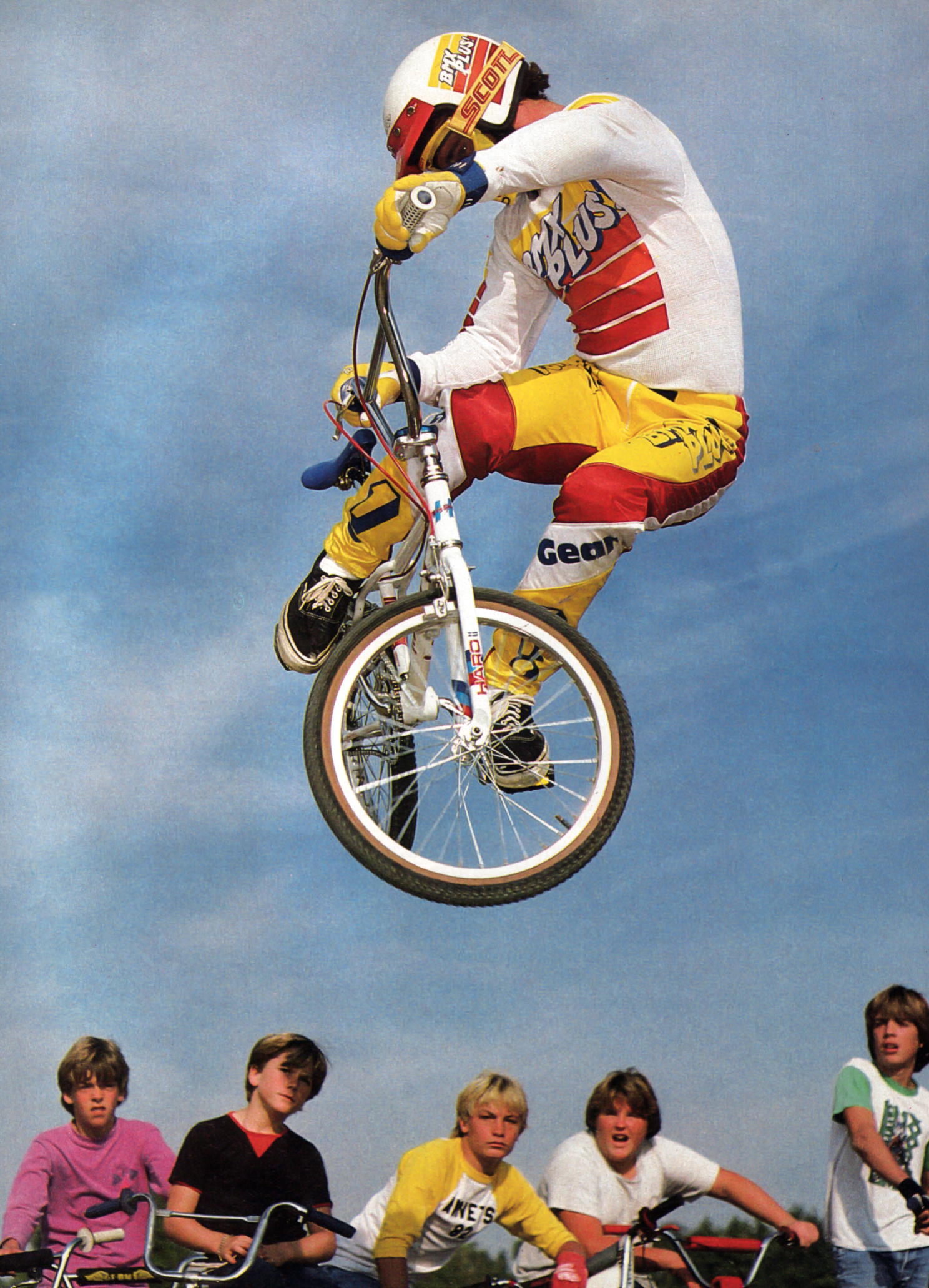

The 1983 King of the Skate Parks contest series became the catalyst for a new generation of riders to step up and lead freestyle into its competitive era. Mike Dominguez and Rich Sigur were members of a community that redefined the limits of pool riding in the early 1980s – blazing a trail for others to follow. The early freestyle pioneers - Bob Haro, RL Osborn, and Mike Buff - were their inspiration. Skate City, in Whittier, The Pipeline Skate Park, in Upland, and the Skate Ranch, in Del Mar, became their proving grounds. During a two-year window, between 1983 and 1985, this committed community of teenagers evolved and reinvented the future of vert riding on a weekly basis and gave rise to a phenomenal alternative sport.

Both Dominguez and Sigur joined Haro in the late summer of 1983. Both agreed that the Haro Freestyler - the only dedicated freestyle bike in the market at the time - was not the ideal vehicle for skate park riding. In Sigur's case, he simply couldn't ride it and reverted back to his longer Supergoose frame and fork. Dominguez, though, had previously ridden a Torker frame and was familiar with the twin-top-tube format, but he had opted to ride the longer Skyway TA while representing the Vans Team, and soon ran into the same issues as Sigur where the limitations of the Freestyler was concerned. The new Haro Master entered the market in the spring of 1984, but the Master was built around the same tried-and-tested geometry as the Freestyler and was ideally suited to flatland riding. With the lack of an existing solution, the opportunity to deliver another breakthrough technology in the freestyle market became Bob Haro's priority.

The Haro Sport was developed in partnership with frame builder, Torker BMX, based in Fullerton, Orange County. Its geometry and design were based on a frame and fork concept with a longer wheelbase and a slacker steering angle. On the morning of March 18th, 1984, Mike Dominguez and Rich Sigur arrived at the Del Mar Skate Ranch for round 2 of the AFA King of the Skate Parks series. Both riders unpacked a prototype frame and fork; built with their cosponsors equipment. Sigur's frame was chrome, with a single top tube and a rear triangle that resembled the "Haro Freestyler Master" frame drawing. Dominguez's frame was white and also featured a barrel-straight single-top-tube, identical to the model seen in the Haro "Trick or Street" advert shot earlier that week in Carlsbad. The rear triangle of the white frame, although longer, was built from a Haro Master tube, and dropout set. Dominguez placed 1st at the Del Mar contest in the recently formed Pro category, and within a month he appeared in BMX Action Magazine cradling a production version of the frame in his arms, while pointing to a decal on the dropout that read "Mike Dominguez."

In the summer of 1984, the Haro Sport went into full production with Torker. The new package was stable on the ground, and in the air, thanks to its long wheelbase, derived from its 19'5" top tube, a 74-degree steering angle. The Sport also now featured a standing platform around the seat mast, and its arrival marked the launch of the first dedicated vertical trick bike in the history of the sport.

The FST - Freestyle, Street, or Track.

The FST (Freestyle, Street, or Track) was the relative latecomer to the Haro Freestyle bike line up in 1984. Specifically designed as an affordable, entry-level option, this versatile complete bike was launched in a dedicated advertising campaign, titled, "Get Started in Style" in February 1985.

At first glance, the FST resembled the Haro Sport - both models featured a standing platform around the seat mast - but closer inspection of the FST reveals the key differences that made it less expensive to produce. The FST's top tube measurement was identical to that of the Haro Master at 18.5 inches, with similar seat mast and head tube angles. Further manufacturing savings were made in the removal of the gusset on the rear chain stays, and neither the head tube or the bottom bracket shell was machined to reduce weight. The '84 FST was only available for sale in white, as a complete bike, and it featured its own graphic scheme, utilizing a red band in the decal to differentiate from the Master (green) and Sport (grey). The majority of the Haro FST's were produced in Taiwan by Anlen, and Anlun, although a small batch of frames was produced by Torker in November of 1984 prior to their chapter eleven filing. These frames are rare and constructed from tubing with noticeably thin wall thickness. The seat mast gusset on the Torker built frames also sits on top of the standing platform, and the frame featured a series of weep holes presumably inserted to dissipate heat when welding the thinner-walled tube set.

Some of earliest images of the 1984 FST appeared in a bike test article featuring Haro team rider Tony Murray at the Del Mar Skate Ranch. This particular frame was clearly still in development with no reinforcing gusset at the head tube and down tube junction, although this feature was introduced to the full production model. The rear dropouts were identical to those used on the US Made Sport’s and Master’s. Although it was only produced in modest quantities during October and November of 1984, the FST was marketed internationally well into the spring of 1985. The arrival of the next evolution of the Haro FST in 1985 included an expansive range of colors options - most notably a neon red version seen in the “Alone at the Top” advert featuring new Haro recruit, Brian Blyther, and shot by James Cassimus at the Del Mar Skate Ranch.

The Neon Years - 1985 and 1986.

The year's 1985 and 1986 became the boom years for the formative freestyle industry. The new sport had put down deep roots in the US, Europe, and Australia, with lines of distribution channeling a profusion of bikes, clothing, and accessories, into a global market. Inevitably, many of the BMX race and component brands recognized the shift in emphasis and began to develop their own freestyle specific products. The battle for market leadership played out in the neighborhood bike shops, and on the pages of the BMX media. In the mid-1980s, It was hard to deny this formidable new direction for BMX.

Haro's relationship with its Asian manufacturing partner was off to a productive start. The Wong's capacity to produce and assemble high volumes of the Master, Sport, and FST, along with Torker's continued output of frame and fork sets in California, enabled Haro to launch a series of promotional campaigns and equip its growing freestyle team with state-of-the-art equipment. But the sheer volume of production in 1984, coupled with Haro's ambition to stay ahead of the curve with its market-leading bike range, made 1985 another challenging year in the supply chain.

The redesign process began on October 2rd, 1984, when a prototype drawing for a new Haro Master and Sport were raised at Anlen. Bob Haro worked alongside the company’s engineers to overhaul the geometry, molds, raw material specifications, and graphic scheme, of his entire range. A prototype of the 1985 Master was produced around the same time with several new features and standards born from Haro's vision for the next chapter of the sport.

A first draft of the technical drawing featured a frame with a 65-degree seat mast angle – a significant modification from the 1984 Master which featured a corresponding 68-degree angle. This is one of a series of experiments that were aborted on the full production model, which ultimately settled at 69 degrees. The reinforcing gusset plates, located between the top tubes and behind the bottom bracket shell featured pressed-in chevron logos. This feature was also dropped for full production in favor of the small circular hole seen on the 1984 frames.

The evolution of this final geometry would set the tone with a series of upgrades to the 1985 Master and Sport. Both models now featured a completely redesigned rear triangle. Double s-bends chain stays enabled more wheel and foot clearance and fed into rear dropouts that now had standing platforms incorporated into the design. The fork received attention too, with bolt through steel standing platforms and tapered legs. The final version of the drawing, produced on March 13th of 1985, sent the 1985 Haro Master into immediate production.

The first 1985 frames seen in the BMX press were those supplied to the Team Riders. Ron Wilkerson, Brian Blyther, and Dave Nourie all received new frames in January of 1985 and during this period, the first of the 1985 adverts, 'Alone at the Top" was published in FREESTYLIN' Magazine. Dave Nourie received a Neon Green Haro Master, Blyther a Chrome Haro Sport, and Wilkerson a Blue Sport. All three frames had January serial numbers - stamped at an odd angle in the non-drive side dropout. None of the frames had brazed-on cable guides, and they all featured a primitive knurling texture on the chainstays that was more refined on the post-March production models. By February of 1985, other members of the Haro Team were riding the new '85 frames. Dennis McCoy and Mark McGlynn put the new '85 Haro FST through its paces at round 2 of the AFA Masters Contest Series held in Pleasanton, Northern California. Images of Tony Murray and Rich Sigur, albeit with 1984 decals, also emerged in the BMX press.

As full production of the bike range finally commenced in March of '85, the opportunities to review, and refine certain features, led to minor variations in the final specification. The first production frames arrived in the US in May, with characteristics that were uncommon on later models. Beyond April of 1985, the Master appeared to have a shallower down-tube gusset, identical to the version used on the Sport that required more clearance due to the thicker diameter of its top tube.

As the 1985 bikes made their way into the market, in a bid to get ahead of the manufacturing curve, Bob Haro turned his attention to the design of the 1986 model line. The redesigned 1985 models were well received, and Haro saw no reason to reinvent geometry that was considered to be the best in the scene. Added pressure on the supply chain would also complicate the situation. Anlen had the added responsibility of producing Haro's new Group 1-RS, Racing bike range, as well as a variety of Haro branded components that included handlebars, stems, and Group 1 cranks.

The 1986 Haro Masters and Sports featured the highest specification of any model produced by the company in the 1980's era. In response to the impressive demand for the 1985 Master, Sport, and FST, Jim Ford and Bob Haro adjusted their forecast to almost double the unit quantity ordered the previous year. Manufacturing of the 1986 ranges began in around October of 1985 - and many feature 1985 serial numbers. The advantages of using existing fixtures and tooling enabled autonomy, with the only structural modification on the 1986 models relating to the fork stander – which now hinged up and was located lower on the fork leg. The 1986 Haro Master and Sport also featured a full skin of chrome plating, allowing the rear triangle, and the lower section of the fork legs to remain exposed beneath the paint. In a few isolated cases, only the rear triangle of the frame received chrome, although this is only the case on earlier models and may have been a cost-saving measure.